Lime in Civil Engineering

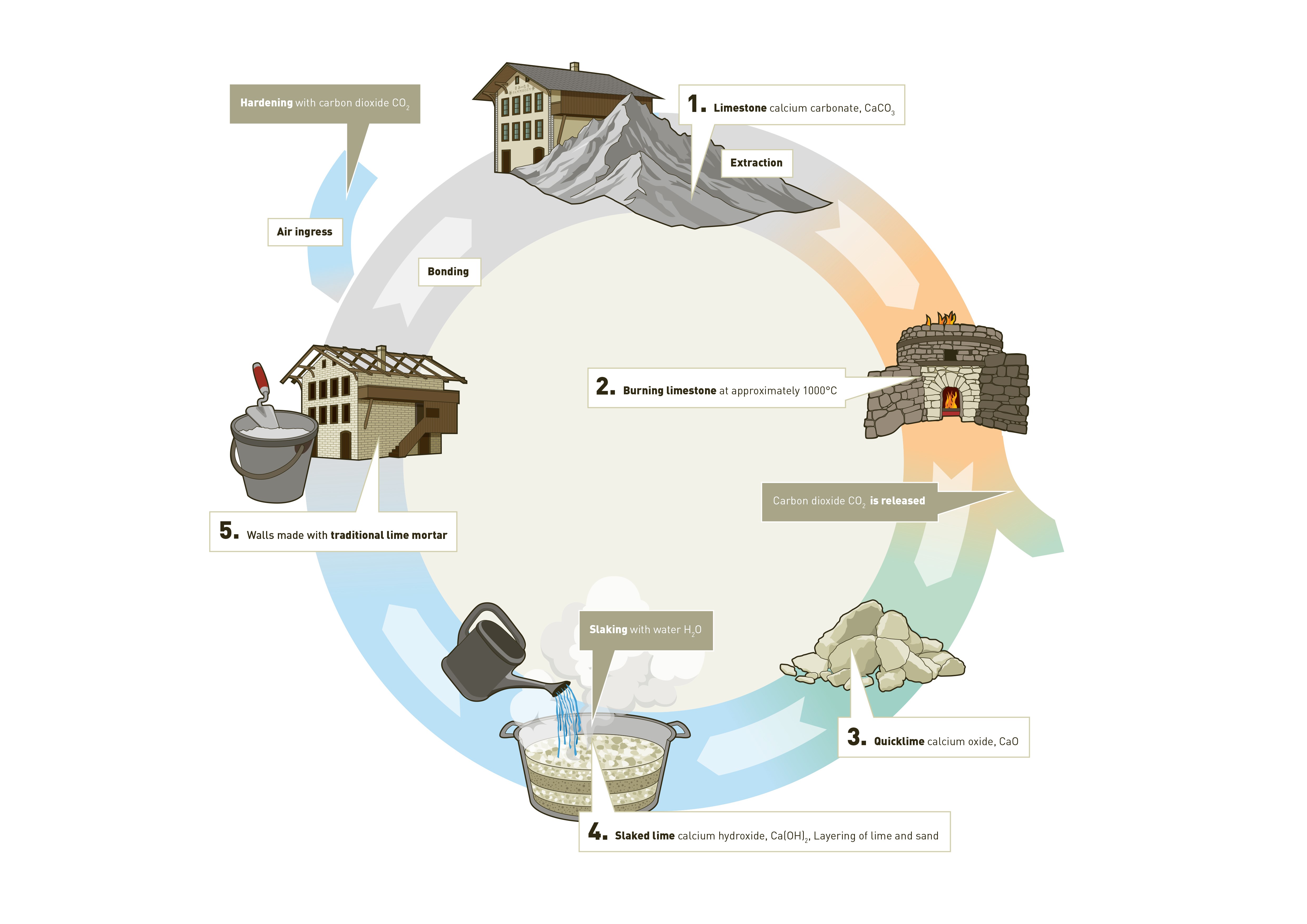

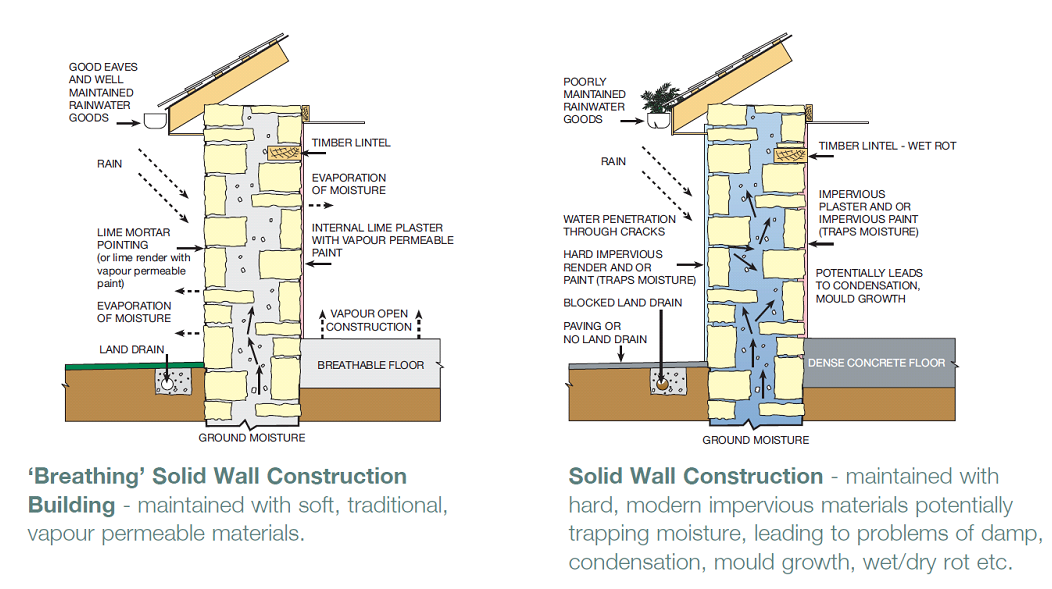

Lime is a traditional binding material derived from limestone (calcium carbonate) through calcination (heating to 900–1000°C). It has been used in construction for thousands of years and remains relevant today, especially in sustainable, breathable buildings, restoration of heritage structures, and eco-friendly alternatives to cement. Lime allows moisture vapor to pass through (breathability), preventing damp issues in older buildings, and it hardens via carbonation (absorbing CO₂ from air).

Manufacturing Process

- Calcination: Limestone → Quicklime (CaO) + CO₂.

- Slaking: Quicklime + Water → Hydrated Lime (Ca(OH)₂) + Heat (exothermic reaction).

Types of Lime

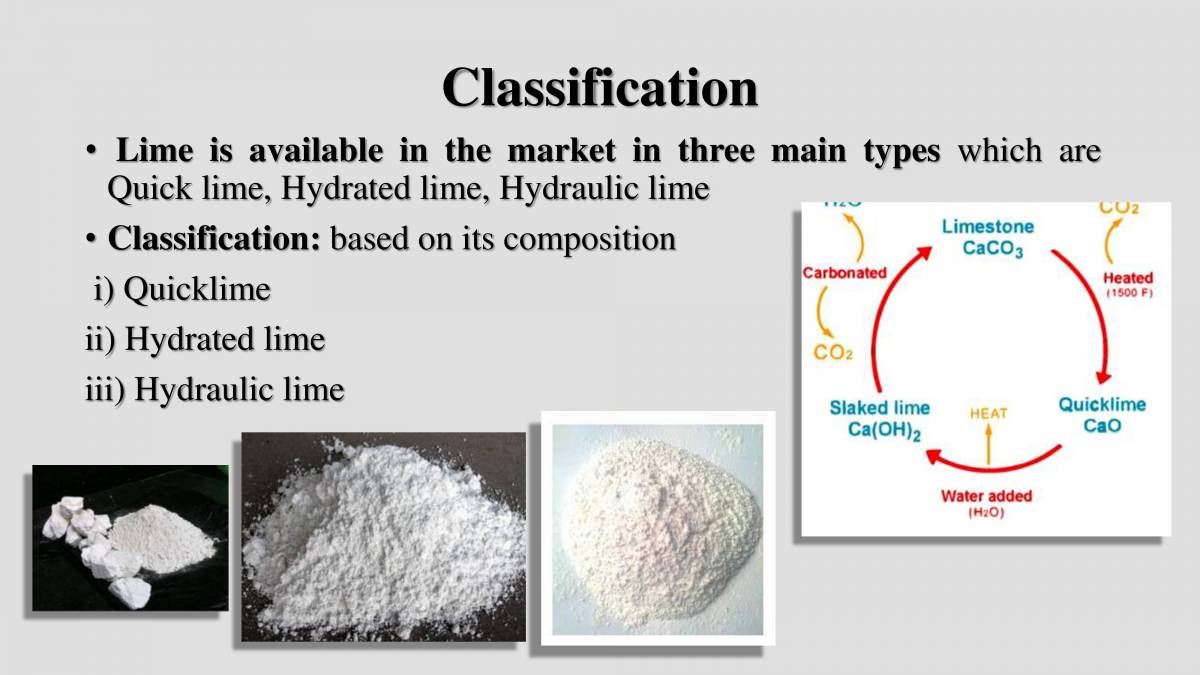

Lime is classified based on purity, hydraulic properties, and form:

| Type | Description | Hydraulic? | Setting Mechanism | Common Uses | Key Properties |

|---|---|---|---|---|---|

| Fat/Non-Hydraulic Lime (High Calcium Lime) | Purest form (>90% CaO); slaked to putty. | No | Carbonation (slow, air-only) | Plastering, pointing, whitewashing | Highly breathable, flexible |

| Hydraulic Lime | Contains impurities (clay/silica); sets underwater. Subclasses: Feebly (NHL 2), Moderately (NHL 3.5), Eminently (NHL 5). | Yes | Hydraulic + Carbonation | Foundations, damp areas, masonry | Faster setting, higher strength |

| Hydrated Lime | Dry powder form of slaked lime. | No | Carbonation | Mortar mix, soil stabilization | Easy to handle |

| Quicklime | Unslaked (CaO); highly reactive. | Varies | Slaking required first | Rarely direct use; for slaking | Caustic, generates heat |

Properties of Good Lime

- Purity: High calcium content; low impurities.

- Plasticity/Workability: Forms smooth putty.

- Setting Time: Non-hydraulic: slow (weeks/months); Hydraulic: faster (days).

- Strength: Lower than cement but sufficient for traditional loads.

- Breathability: High vapor permeability.

- Self-healing: Minor cracks fill via ongoing carbonation.

Introduction to Lime - Lime - Properties

Uses in Civil Engineering

- Lime Mortar: For brick/stone masonry; ratios like 1:3 (lime:sand).

![HOW TO MIX LIME MORTAR [Bricklaying for beginners e.p 6]](https://i.ytimg.com/vi/utrT3dMFkRM/maxresdefault.jpg)

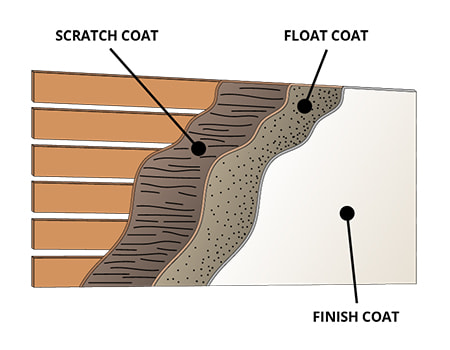

- Lime Plaster: Internal/external finishes; typically 3 coats (render, float, set).

- Soil Stabilization: Improves strength of clay soils.

- Whitewashing: Decorative and antiseptic coating.

- Restoration: Essential for historic buildings to match original flexibility.

Advantages Over Cement

- Eco-friendly (lower CO₂ in production, reabsorbs CO₂ during setting).

- Flexible (accommodates movement, reduces cracking).

- Breathable (prevents trapped moisture).

Lime requires skilled application due to longer setting times but excels in sustainable and heritage construction projects.

Tags:

Building Materials